Products / Beam welding line / Horizontal solutions

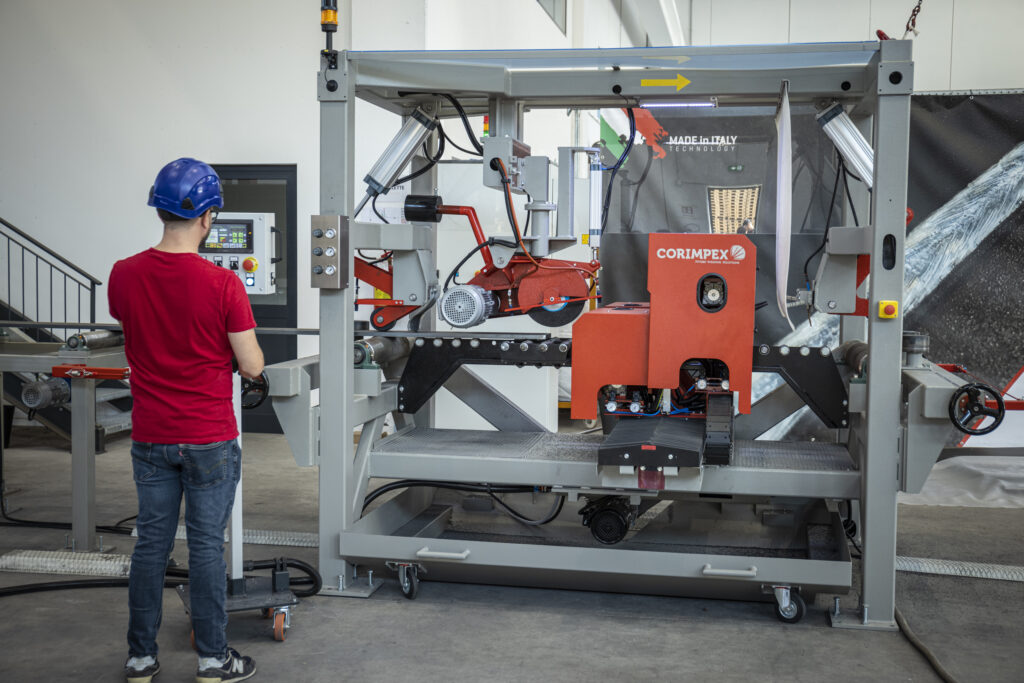

HFI – Horizontal Fully Integrated

Combined line for horizontal welding of straight, conical and shaped beams.

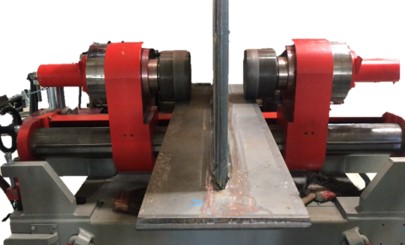

The HFI horizontal welding line is the combined engineering solution for the production of H-beams with variable shape and inertia, double-tapered beams and K-shaped beams. The line consists of the manipulator (CB – Column & Boom) with double welding heads, assembly jig (HAJ – Hydraulic Assembling Jig), 180 ° rotators and the horizontal straightening machine (BSM – Beam Straightening Machine). The solution makes this line one of the most used in the field of PEB and one-side welding applications.

| HFI 2000 x 600 |

HFI 2500 x 800 |

|

|---|---|---|

| FLANGE THICKNESS | 6 – 40 mm | |

| WEB WIDTH | 200 – 2000 mm | 200 – 2500 mm |

| MAX BEAM WEIGHT | Custom | |

| WEB THICKNESS | 5 – 20 mm | |

| BEAM LENGHT | Custom | |

| CONVEYOR’S TRAVEL SPEED | 8 m/min | |

| FLANGE HEIGHT | 150 – 600 mm | 150 – 800 mm |

| TYPE OF WELDING | Submerged arc: Twin-arc / Single wire | |

In Corimpex we produce high-quality accessories and we provide an efficient after-sale service, which confirm the reliability of a Made In Italy company, world leader in the industry segment.