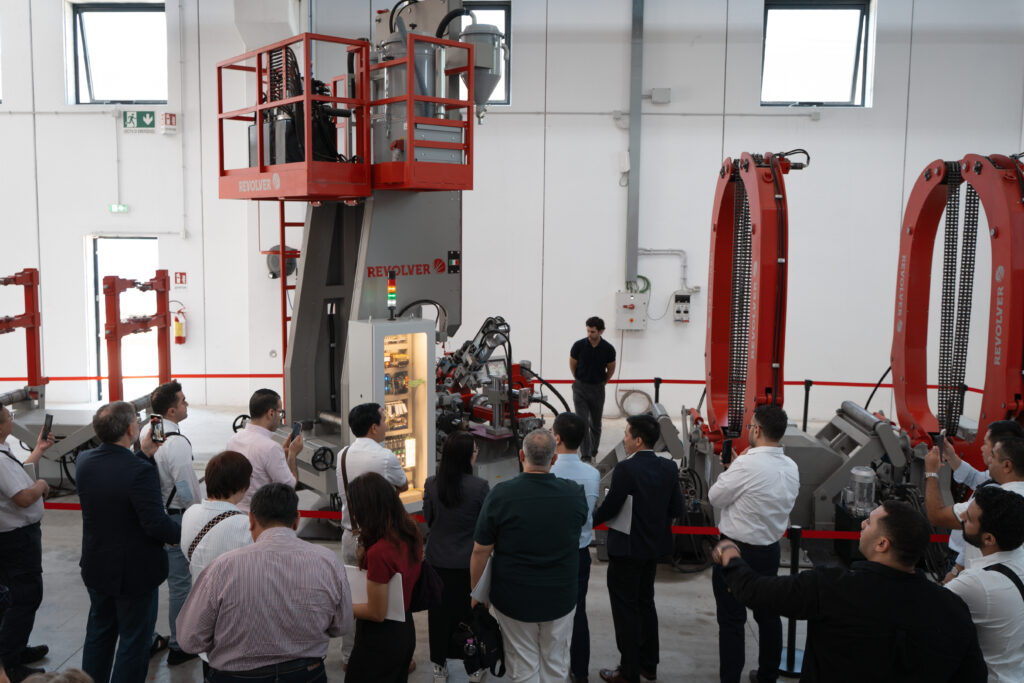

FICEP & CORIMPEX OPEN HOUSE 2025

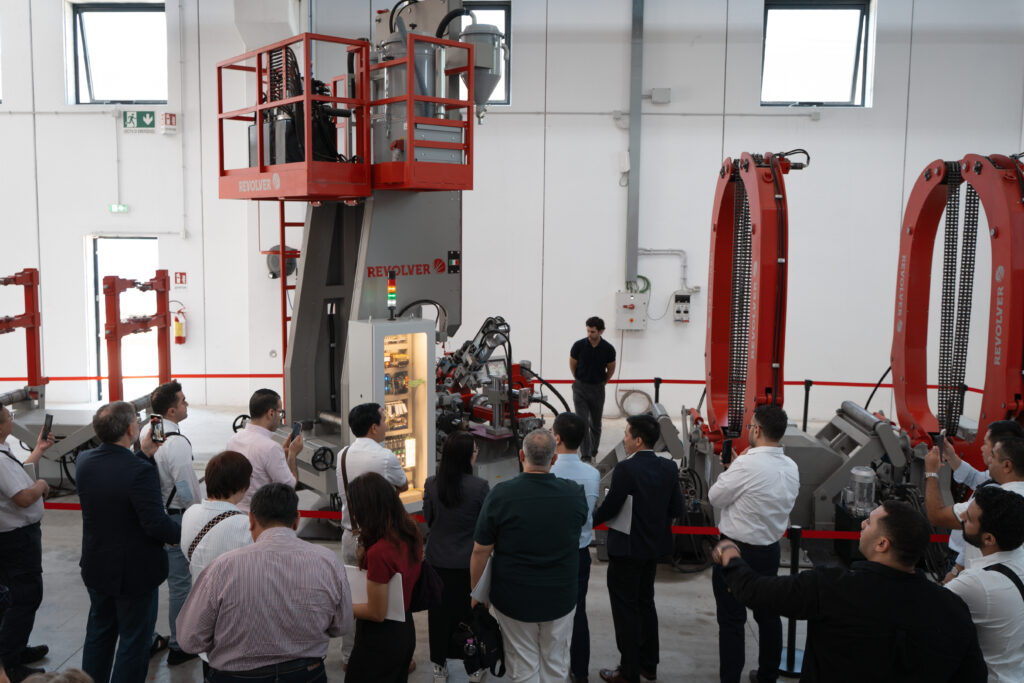

Ficep and Corimpex present the new OPEN HOUSE 2025 – June 23-27. We have been pleased to open the doors of our headquarters and plants

The Company

Corimpex is recognized as a world leader in the engineering, production and installation of solutions for arc-welding-automation, with a strong commitment to optimizing the entire welding process. Starting from a strong technical background, Corimpex has developed its core business in the automation of submerged arc welding, which makes it the only Italian company with such specific skills, backed by almost 50 years of experience in the sector. Our products are assembled and tested in our Italian production sites with accuracy, quality and professionalism by our experienced staff. The establishment of our branch office in Dubai has also strengthened support for the Middle Eastern and international commercial network.

What’s SAW?

Submerged Arc Welding (SAW – Submerged Arc Welding in AWS terminology) is a wire arc welding process characterized by the use of welding flux. The flux is deposited following the welding line, in order to get the best quality possible. This kind of welding process find its application in specific industrial segments.

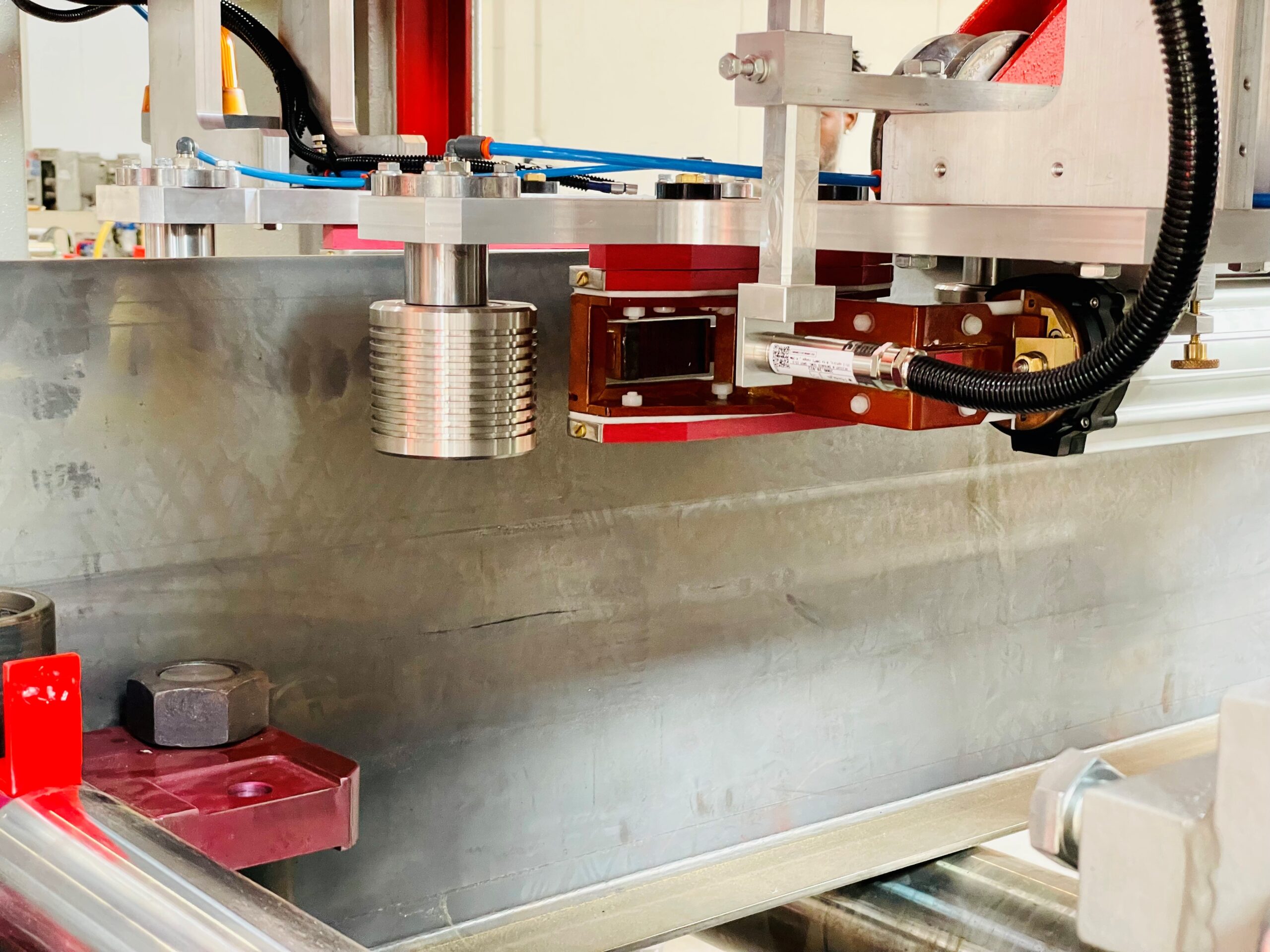

It represents the worldwide most advanced and flexible automatic solution for the production of welded beams. This line allows customers to reach the highest level of productivity thanks to the less needs of the overhead crane, no requirements of pre-tack weld, integrated flange straightening device and many other options.

These lines are designed for the segment of the lighting steel poles, telecommunication or transmission towers. The PWL represents the most productive solution thanks to the unique reacheable dimensions of work on the market.

A specific line of machines to prepare just-in-time your steel plates before or after the welding process, improving the overall productivity and quality of your workshop.

The latest and innovative lines to cover all your straightening needs to meet your steel construction tolerances. Flange distortion, undesired camber and sweeping are no more an issue.

The TCW line has been engineered on welding fixture to optimize the productivity of the trailer chassis fabrication. The main distinction of this line is the ability on following shaped beams during the welding process.

A wide range and sizes of sub-arc welding Column & Boom and rotators for many different industry segments such as of Oil & gas, wind towers, pressure vessels, boilers and petrochemicals.

Our patented innovative solution in the field of welded H, T and I beams. A single Beam welding system that allows to manufacture the beam without the need of the overhead crane during the whole production cycle.

Worldwide customer service

Solutions at your fingertips for the request of spare parts, assistance and the quick updating of the ticket status to ensure information in real time to our customers.

A complete range of high quality spare-parts, to maintain high level of efficiency and productivity of the production lines.

The reliability of the company and our systems is confirmed by pre and post sales support, followed directly by our staff via ethernet.

Skilled experts from selected local countries are available for immediate assistance and ensured by our quality standards.

Where you can find us?

A quick and efficient support, provided in collaboration with our international partners, is one of our top priorities. Corimpex can count on an excellent sales and after-sales network, offering technical support in more than 83 countries around the world.

Updates from the Corimpex World

Ficep and Corimpex present the new OPEN HOUSE 2025 – June 23-27. We have been pleased to open the doors of our headquarters and plants

Our sales team represents Corimpex in many unmissable events in May 2025 – discover which are these major fairs all around the world. AFRICA The

When structural fabricators are asked to weld custom beam sizes, they usually first ask if those custom sizes are truly necessary. They sometimes are, especially