Products / Revolver solution / Patented

REVOLVER™

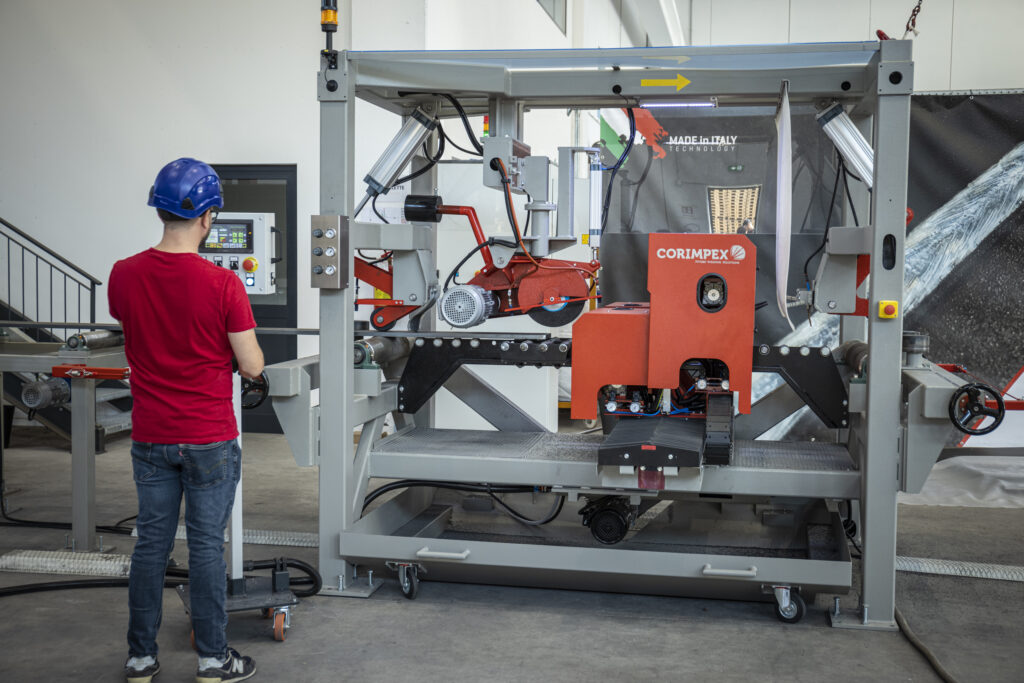

Revolver ™ System, the beam welding line designed to maximize productivity and minimize production costs.

Our latest and revolutionary global technological innovation in the field of welded beams is represented by the REVOLVER ™ Solution.

It represents the first beam welding system that allows you to compose and weld an H-beam without the need for an overhead crane during the entire production cycle. Revolver ™ is designed to assemble and weld the first T-beam and automatically manage its 180 ° rotation before welding the second flange and completing the beam welding by further rotating the machine 180 °. Among the considerable advantages that distinguish this solution we certainly find the 150% increase in productivity compared to a standard single line, enormous space saving (-60%), labor savings (-135%), greater safety and noise level drastically reduced.

Revolver is therefore the ideal choice when there are severe limitations in the use of the bridge crane, space limits and high productivity requirements.

| REVOLVER™ 1500×800 |

REVOLVER™ 2000×1000 |

|

|---|---|---|

| MACHINE ROTATION SPEED | 180° / 50 sec | |

| ROTATION ANGLE | 180° | |

| CONICAL BEAMS | up to 15 ° of inclination | |

| MAX BEAM LENGHT | Custom | |

| MAX BEAM WEIGHT | 800 kg/m | 1.200 kg/m |

| FLANGE WIDTH | 100-800 mm | 150-1000 mm |

| WEB HEIGHT | 150-1500 mm | 200-2000 mm |

| TYPE OF BEAM | H – I – T – WIDE FLANGES – ASYMMETRIC BEAMS | |

| CONVEYOR’S TRAVEL SPEED | 12 m/min | |

| MAX CYLINDER STROKE | 1350 mm | 1800 mm |

| TYPE OF WELDING | Submerged-arc: Single wire / Twin-arc / Tandem / Tandem Twin | |

In Corimpex we produce high-quality accessories and we provide an efficient after-sale service, which confirm the reliability of a Made In Italy company, world leader in the industry segment.