Products / Plate preparation lines / Web beveling

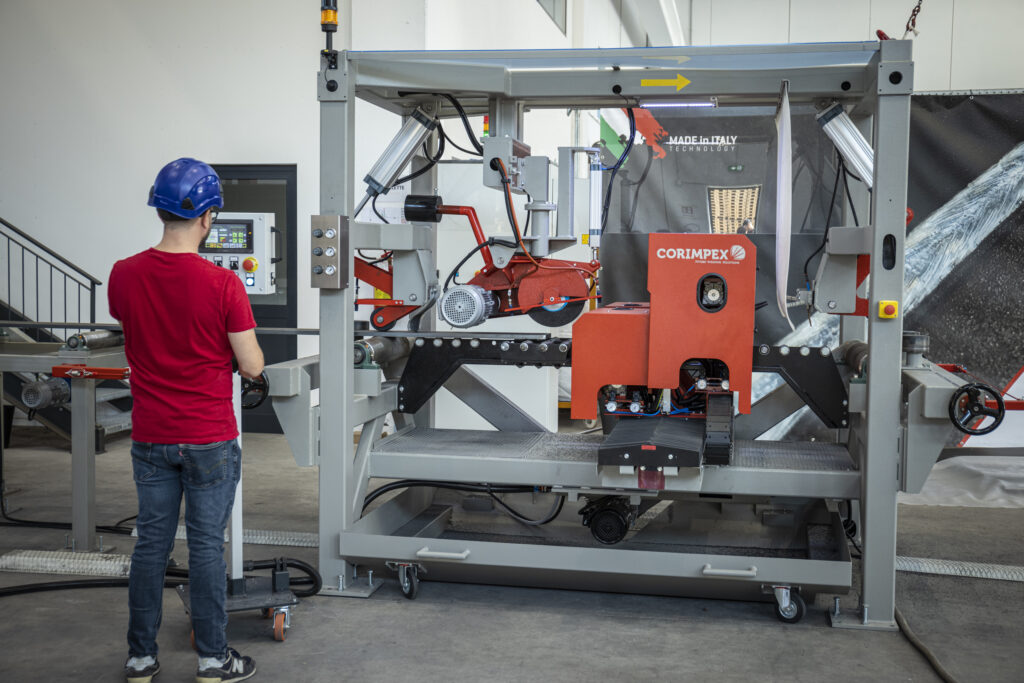

PWB – Plasma Web Beveling

The PWB is the ideal solution to crimp both sides of the steel plates simultaneously using Plasma or Oxy-fuel technology

The PWB – Plasma Web Beveling, is a unit with 4 cutting torches (Plasma / Oxy-fuel) for the preparation of both edges of the steel plates: preparation of K-shaped grooves optimized for full penetration welding of the highest quality. The PWB can be combined with the FEMS-R – Flange Edge Rounding S, thus generating a flexible line for the preparation of flanges and webs in order to optimize the subsequent welding processes. The use of a PWB unit saves hundreds of hours of manual work and greatly optimizes the productivity of subsequent beam welding processes by making the plates quickly available.

| PWB 2000 |

PWB 2500 |

|

|---|---|---|

| PLATE LENGHT | Custom | |

| CUTTING SPEED | 0,5 – 1,5 mm/min | |

| MIN. PLATE THICKNESS | 8 mm | |

| MAX PLATE THICKNESS | 30 mm (larger thicknesses on request) | |

| N° OF PLASMA TORCHES | 4 | |

| MIN. PLATE LENGHT | 550 mm | |

| MAX PLATE WIDTH | 2000 mm | 2500 mm |

| BEVELING ANGLE | ± 50° | |

In Corimpex we produce high-quality accessories and we provide an efficient after-sale service, which confirm the reliability of a Made In Italy company, world leader in the industry segment.